INSTRUMENT CALIBRATION SERVICES

Calibration process

All GL Optic instruments are individually calibrated for the end-user during manufacturing to ensure the highest accuracy of each and every delivered system.Before the actual calibration process, five pre-calibration stages are performed.

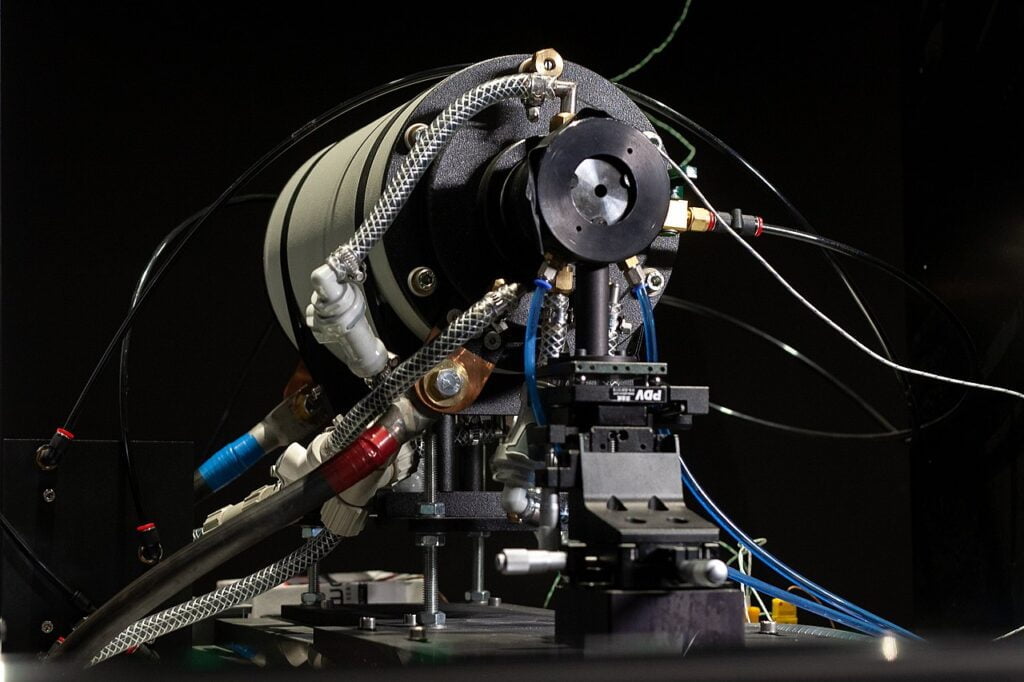

Photometric and radiometric calibrations

In order to enable the accurate measurement of different absolute values such as lux, candela or lumen together with radiometric values depending on the measurement accessory installed, an absolute spectral calibration is integrated into each spectroradiometric system before delivery.

Extended UV and NIR spectral calibrations

Our unique expertise and calibration facilities allow for accurate spectral calibrations starting from ultraviolet UV-C 200 – 280 nm, UV- B 280 – 315 nm to UV-A 315 – 380 nm ranges. For specific instrumentation, we can offer extended NIR calibrations from 780-2400 nm.

Our laboratory calibration services

We offer multi-step calibration services performed in our CARLO laboratory (Calibration and Research Laboratory of Optical Radiation).

What is the calibration process like?

See the individual steps

Dark current compensation

Under different integration time and temperature CCD and CMOS sensors used in spectroradiometers generate certain level of noise even if they don’t receive any radiation. The level of that noise is mostly affected not only by the temperature of the sensor itself but also the integration time. Calibration process includes the above properties and allows to compensate for the changes of background noise in relation to the conditions during the measurement.

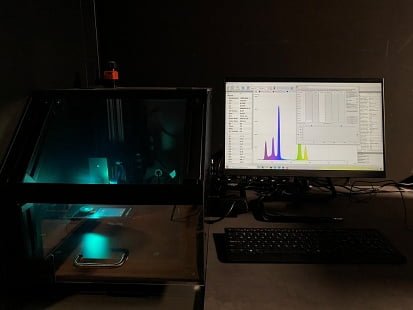

Wavelength reproducibility calibration

Each pixel of the spectroradiometer’s array sensor detects a very narrow degree of the whole spectrum tested. Therefore, each of those pixels must be precisely assigned to the wavelength it is responsible for. The procedure uses the spectrum of Hg-Ar low pressure lamp as a standard. The spectrum contains multiple narrow peaks of precisely known centre wavelength. Procedure compares received sensor readings to the known values and compensates for wavelength shift of each pixel.

Stray light compensation

Some small amount of light that enters spectroradiometer is reflected in an uncontrolled manner within its optical system as it enters the array sensor from random directions. This creates unwanted detected signal over certain areas of the sensor that is not the real picture of the observed spectrum. This property is also wavelength dependant. The procedure characterises the acting of the sensor by testing the response to narrow parts of the spectrum restricted by bandpass filters across the entire range covered.

Sensor non-linearity correction

The electrical response of the sensor to radiation energy received is not linear. Doubled radiation level should result in a doubled reading. The procedure compares the sensor response to actual signal levels measured in multiple steps across the entire dynamic range.

Absolute spectral calibration

The main idea behind spectroradiometer is to determine exact amount of optical radiation incident on each photosensitive element of array detector which represents particular wavelength in entire measured spectral range. The obtained set of values constitutes result of spectral measurement and allows for calculation of photometric, radiometric and other parameters characterizing optical radiation. The purpose of calibration procedure is to establish for each element of array detector a relation between obtained indication and true value. The procedure includes measurement of light source – a standard of know spectral distribution, and then comparison of measurement result with values from standard’s certificate of calibration. Depending on calibrated system, the procedure uses spectral standards of irradiance, radiant flux or radiance.

Onsite calibration service

On demand, Total Spectral Luminous Flux and Radiant Power calibrations are offered as an On-Site service. This is recommended mainly for larger sphere systems and dedicated measuring instruments. Such service includes the absolute spectral flux calibration while the remaining preliminary steps are implemented as Model/Type specific parameters.

CARLO calibration includes all the calibration steps performed individually.

Traceability statement

The GL Optic Absolute Spectral Calibration is VNIIOFI, NIST and PTB traceable. It is also traceable to other NMIs ( National Metrology Institutes ) around the world based on the international mutual recognition regulations of BIMP the intergovernmental organization through which Member States act together on matters related to the measurement science and measurement standards.